Services

Our Areas of Expertise

Our products and services have benefited from years of research, innovation and continuous development to attain the durability and resilience expected in Parking lots, Airport, Highways, roadways and regional networks. As an expert road marking company in Sultanate of Oman, we offer a variety of services, including thermoplastic road marking, cold plastic road marking, airport and runway marking, road stud fixing, sandblasting etc.

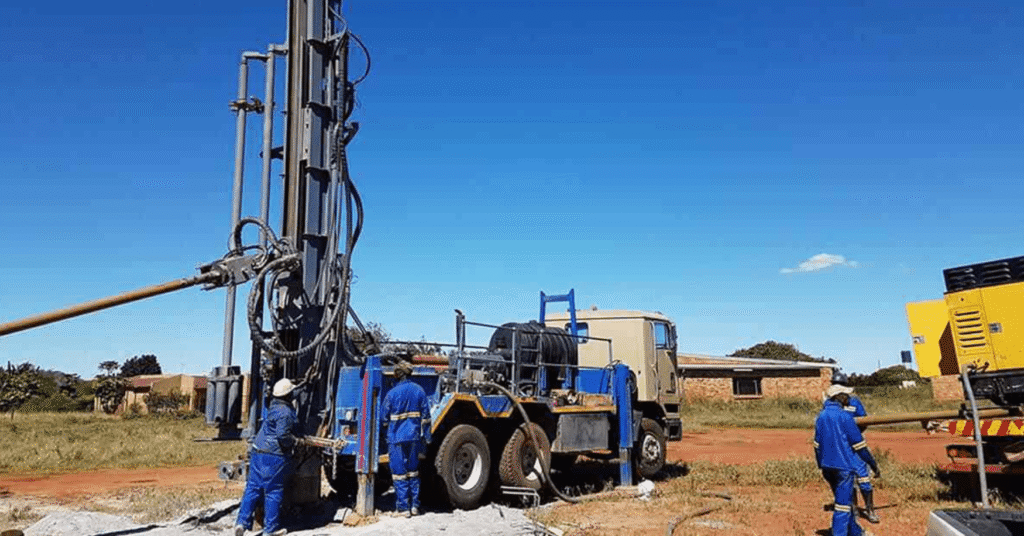

We pride ourselves on being specialist in bore well drilling, Road Marking and have teams of experienced Operators and assistance that are solely trained in well drilling and Road Marking.

Road markings are crucial in keeping highways, drivers and passengers safe.

HDD, is a steerable trenchless method of installing underground pipe, conduit, or cable.

Advanced vertical drilling technology for accurate, cost-effective, and deep underground installations.

Comprehensive drilling solutions for water wells, earthing pits, and bore holes with precision and reliability.

Road Marking Services

1. Thermoplastic Road Marking

Road markings play a vital role in highway safety, and AST brings unmatched expertise in hot thermoplastic road marking across Oman. With a skilled in-house team and state-of-the-art equipment, we deliver durable, high-visibility markings that ensure safety in all weather conditions.

We specialize in screed and preformed thermoplastic markings, extrusion, profiled markings, and road studs. Using premium thermoplastic paint, glass beads, and advanced machinery, our team handles projects of all sizes — from highways to specialty markings like arrows, crosswalks, and stop bars — with speed, precision, and long-lasting results.

2. MMA Cold Plastic Marking

AST provides professional cold plastic road marking services in Muscat and across Oman. Known for its fast curing, durability, and superior reflectivity, cold plastic is ideal for highways, parking areas, service yards, and other high-traffic zones.

Our skilled team uses advanced technology and premium materials to deliver markings that withstand heavy loads, resist dirt, and ensure high visibility in all conditions. Available in various resin colors, our cold plastic solutions can be customized to meet both safety and aesthetic project requirements.

3. Airport & Runway Marking

Line marking is a vital part of airfield infrastructure, ensuring safe aircraft and vehicle movement on runways, taxiways, and aprons. With extensive experience in airport and runway markings, AST delivers precise, durable, and regulation-compliant solutions that enhance both safety and efficiency.

We use Alkyd Base cold paint and advanced technology to provide accurate markings that meet international standards without affecting aircraft performance. Backed by a skilled team, modern equipment, and high-quality materials, AST ensures every project is completed on time with the highest level of quality assurance.

4. Studs – Aluminium / Ceramics

Road studs are essential for traffic guidance and road safety, especially in low visibility and adverse weather conditions. They mark lanes, edges, and hazards, helping ensure the safety of both drivers and pedestrians.

AST provides reflective, non-reflective, and solar-powered road stud installations across Oman, meeting all safety and performance standards. Our expert team installs studs in roads, car parks, warehouses, and industrial sites with precision, using high-quality materials for durability and long-lasting performance.

5. Sand Blasting / Jet Wash

At AST, we use the sandblasting method — an eco-friendly technique combining volcanic sand, heated water, and low-pressure air — to safely and effectively remove road markings.

This process allows us to clear markings from car parks, runways, highways, garages, and loading decks with minimal surface damage. Whether for traffic layout changes, temporary marking removal, or surface relining, our skilled team ensures a clean finish that restores the surface and prepares it for new coverings.

Horizontal Directional Drilling

Horizontal Directional Drilling or HDD, is a steerable trenchless method of installing underground pipe, conduit, or cable in a shallow arc along a prescribed bore path by using a surface-launched drilling rig, with minimal impact on the surrounding area.

Directional Drilling is used when trenching or excavating is not practical. It is suitable for a variety of soil conditions and jobs including road, landscape and river crossings. Pipe can be made of materials such as PVC, polyethylene, polypropylene, ductile iron, and steel as long as it can be pulled through the drilled hole.

Horizontal Directional Drilling (HDD) is a method of installing underground pipelines, cables and service conduit through trenchless methods. It involves the use of a directional drilling machine, and associated attachments, to accurately drill along the chosen bore path and back ream the required pipe.

Directional drilling is a three stage process:

1. Pilot Hole

The first stage consists of drilling a small diameter pilot hole. Drilling fluid is pumped through the drill pipe to the drill bit where high pressure jets and the bit will grind the soils ahead of the drill stem. The drilling fluid will also carry the cuttings back to the entrance pit at the drill rig. Tracking of the pilot hole can be done in several ways depending on the size and complexity of the shot. Smaller shots are done using a walkover guidance system whereas the larger more complex shots have a wire line magnetics type system. With both methods there is a transmitter or steering tool located near the drill head which sends a signal to the location engineer giving the exact coordinates of the drill stem. Readings are constantly taken which check the depth, alignment and percent slope of the drill head.

Corrections will be made by the operator and locator to keep the pilot hole along the predetermined bore path. The speed of the pilot hole will vary upon existing soil conditions and the amount of steering which is required. Upon reaching the exit point, the beacon housing and bit is detached and replaced with a reamer.

2. Pre-Reaming

The second step is to pre-ream the pilot hole and enlarge it to a size sufficient to safely install the product lines. A reamer is pulled back and rotated while pumping drilling fluid to cut and remove solids to enlarge the hole. Pre-reaming speeds will vary depending on existing soil conditions and the amount of cuttings that are removed from the hole.

Bentonite and other additives will be used to ensure a clean and stable hole. Bentonite is used to create a “cake layer” around the outside of the hole during pre-reaming. This will help with the stability of the bore hole and with fluid loss or infiltration. Additives such as polymers are used to help break up the clay soils. A more evenly mixed drilling fluid will prevent any blockages inside of the bore hole.

3. Pipe Pullback

The final step is the pullback of the pipe within the pre-reamed hole. The drill rod and reamer will be attached to a swivel, which is utilized between the product line and the reamer to prevent any torsional stress from the rotating drill string being transferred to the product pipe. As the product pipe is pulled into the drill hole, drilling fluid is pumped downhole to provide lubrication to the product pipe.

Vertical Directional Drilling

Steps Included:

- Site Preparation

- Setting Up Drilling Equipment

- Drilling the Borehole

- Casing and Lining the Well

- Well Development and Testing

- Installing Pump and Filtration Systems

- Well Completion and Landscaping

- Final Inspections

Bore Well, Earth Pit & Bore Holes

Steps Included:

AST offers professional drilling solutions for bore wells, earth pits, and bore holes across the Sultanate of Oman. With decades of expertise and advanced equipment, we ensure accurate, reliable, and long-lasting results that meet the specific needs of each project.

Our skilled team handles everything from water bore wells to earthing pits for electrical safety and bore holes for structural requirements, delivering services with precision, safety, and efficiency. Whether for residential, commercial, or industrial applications, AST provides tailored drilling solutions that comply with all safety and quality standards.

Bore Wells: We offer precise water well drilling to ensure reliable groundwater access, tailored to site-specific geological conditions.

Earth Pits: Our team constructs earthing pits with accuracy, ensuring enhanced electrical safety and compliance with regulatory standards.

Bore Holes: From geotechnical investigations to foundation requirements, we drill bore holes to support structural integrity and site development.

Backed by decades of experience, AST ensures every project is carried out with safety, efficiency, and durability in mind. Our solutions not only meet industry benchmarks but also provide long-term performance for our clients’ needs.

Our facilities

Our facilities are spread over various locations at Barka, Barka-Sannayya, and Al Hafri with spacious office at Barka, well equipped production facilities, storage areas, Work shop and garage all totaling over 12,100 sq. meters.

We have a fleet of over 5 numbers of construction Rig plant,2 HDD Machines, 2 Road Marking Machines, equipment, and one low bed trailer to mobilize Rigs, 3 hiabs and other necessary vehicles, and are authorized by PDO to certify road worthiness of vehicles.

Get a Quote

Ready to Start Your Project?

Partner with AST for reliable drilling, pipeline, and road marking solutions across Oman.

Contact Persons:

Ali Bin Sa ’aid Al Shibli

GSM: 99313867

Managing Director

Jamil Bin Sa ‘aid Al Shibli

GSM: 99438338

General Manager

Nasar Ali Saayid Salim Al Shibli

GSM: 71593788

Marketing Manager

Anas Safarulla

GSM: 92386252

Project & Operation Head